admin

DEVELOPED PRODUCT: INDUSTRY FROM CORDOBA FOR ALL OF ARGENTINA

INNOVATION + QUALITY = NEW PRODUCT A brand new armored truck suffered a crack in the front spring during a trip from Buenos Airesto La Rioja; due to this, Carlos Bazán from “Rioja Frenos” contacted us. The objective was todevelop a replacement for that spring. To begin working on this, the client was asked to sendus both front springs, the

NEW EQUIPMENT TO GUARANTEE QUALITY IN OUR PRODUCTS

NEW EQUIPMENT TO GUARANTEE QUALITY IN OUR PRODUCTS On March,2018 we started working on new equipment to control cracks for magnetizable particles with the use of the latest generation technology. This equipment is unique in its kind as it enables the user to control on pieces of up to 2200mm of length with a single measure, offering us the capacity

KAIZEN TANGO – FAESA – INTI – JAPON PROJECT

PROJECT KAIZEN TANGO – FAESA – INTI – JAPÓN By the end of 2017, FAESA was considered and invited to participate in the Kaizen Tango Project as one of the three companies from Córdoba which would make use of Japanese tools for the continuous improvement in their industrial factories. This programme aimed at improving quality, productivity and competitiveness in Argentinean

NEW DEVELOPMENTS – PNEUMATIC SUSPENSION

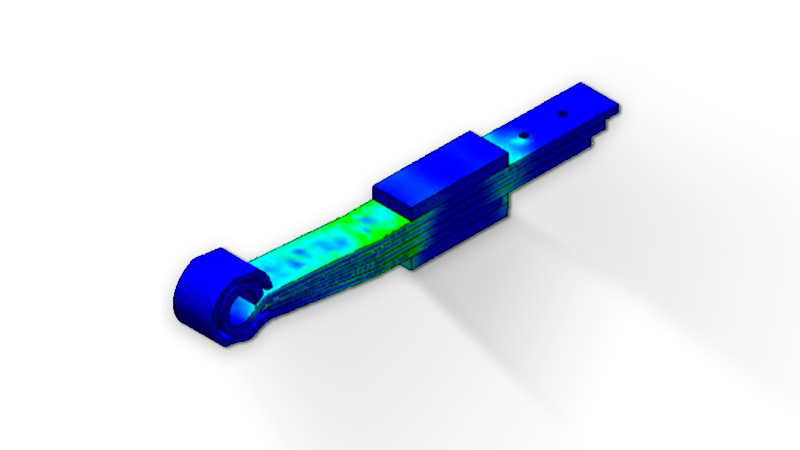

The Engineering Department at FAESA finished in 2017 the field validation stage of the new model of springs for pneumatic suspension which enable us to obtain a significant reduction in weight and better mountability with the same loading capacity. Our designs are validated by our Technical Department by using a calculation software which checks on acceptable stress levels. Along the